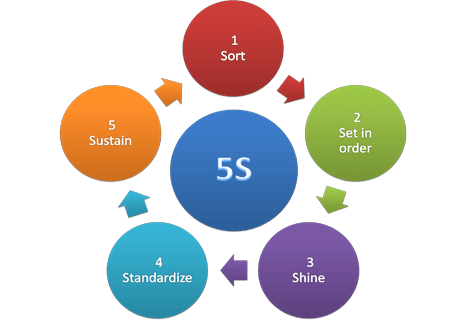

The 5S program focuses on:

- having visual order

- organization

- cleanliness

- standardization

The results you can expect from a 5S program are: improved profitability, efficiency, service and safety.

The principles underlying a 5S program at first appear to be simple, obvious common sense. And they are. But until the advent of 5S programs many businesses ignored these basic principles.

What are the Five Ss?

5S was developed in Japan and stands for the Japanese words seiri (tidiness), seiton (orderliness), seiso (cleanliness), seiketsu (standardization), and shitsuke (discipline). These words have been adopted to English to maintain "5S."

Use the following links to learn more about 5S

Sort

+

The first step in making things cleaned up and organized. This improves efficiency, helps increase quality, and makes it simpler to spot problems and enhances productivity.

Read more »

Set

+

Organize, identify and arrange everything in a work area.

Read more »

Standardize

+

Make it easy to maintain - simplify and standardize.

Read more »

What types of businesses benefit from a 5S program?

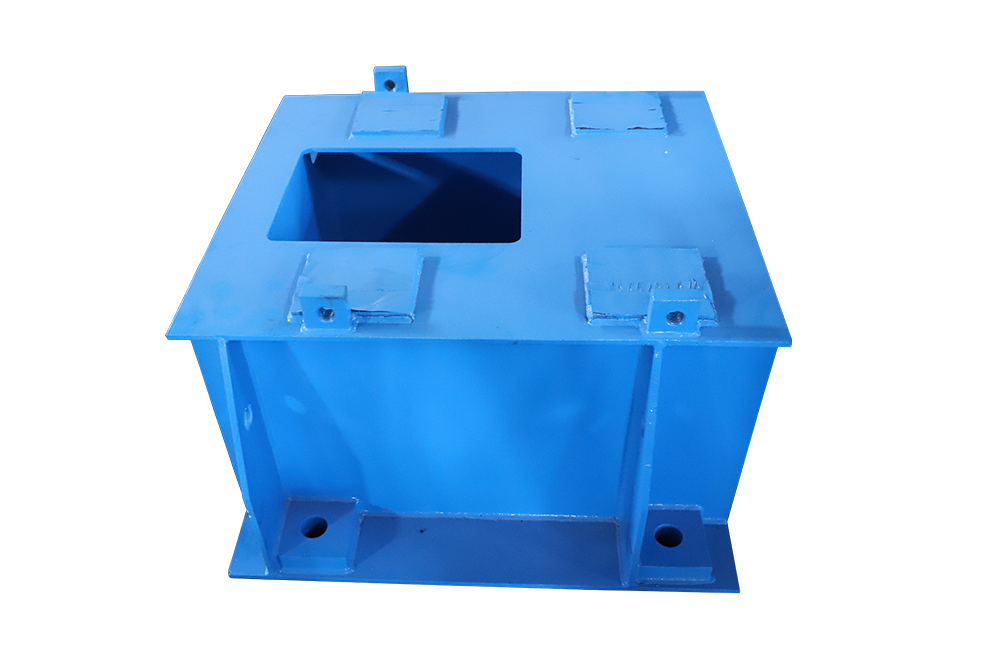

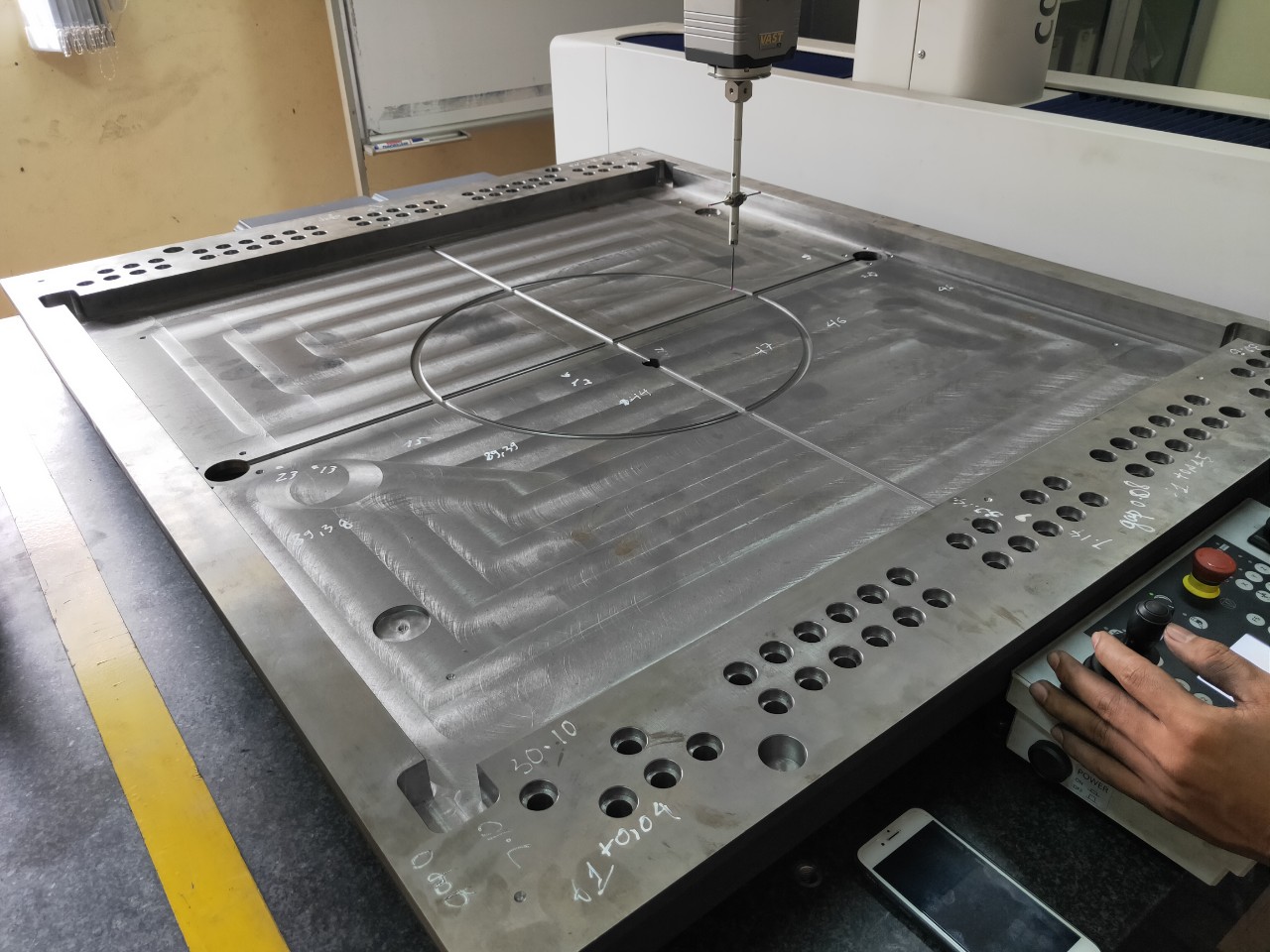

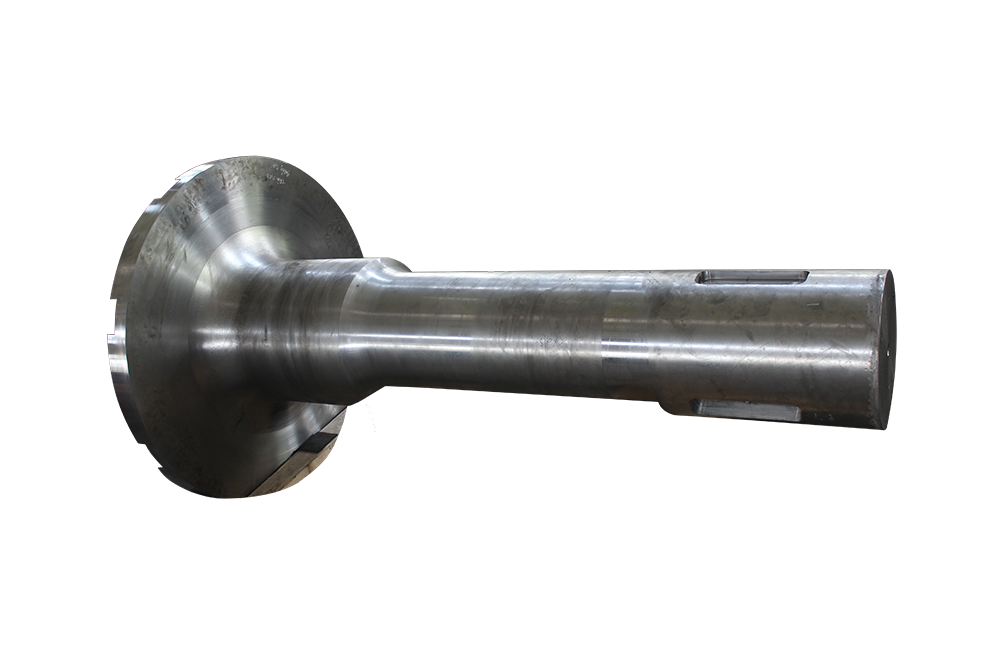

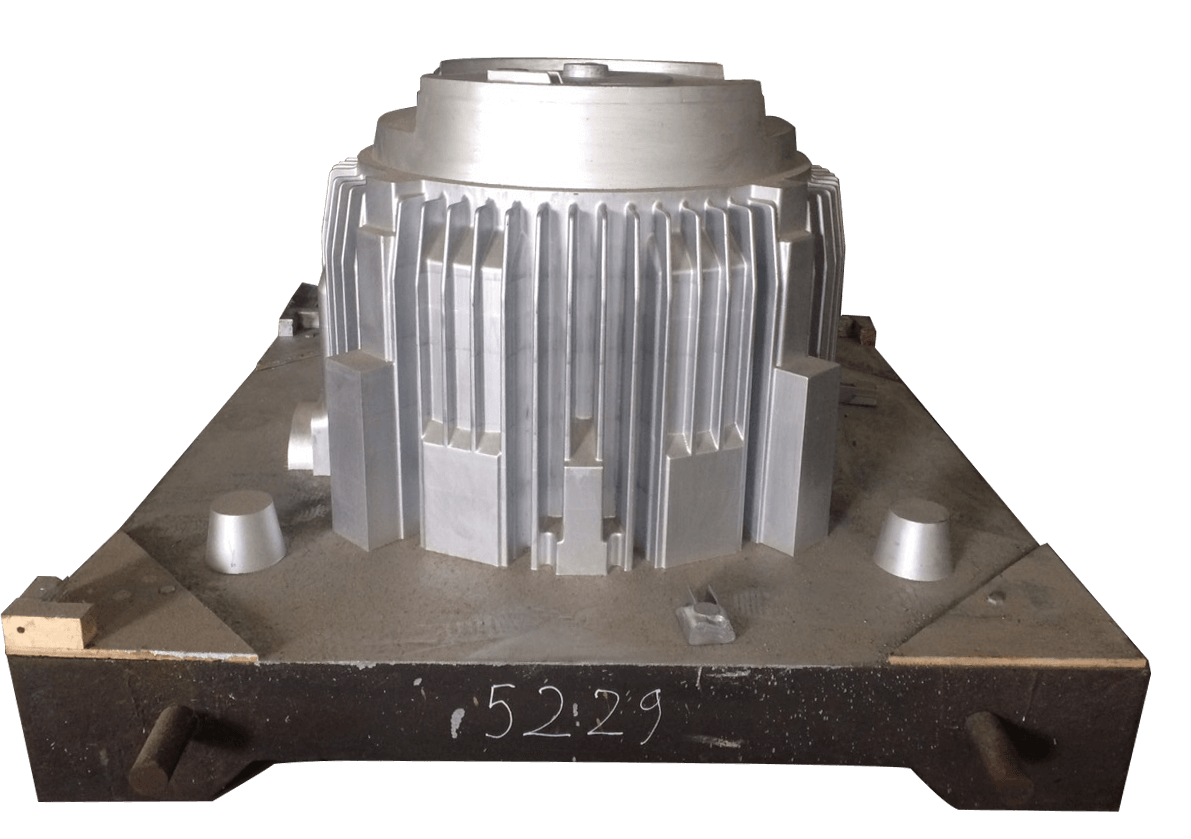

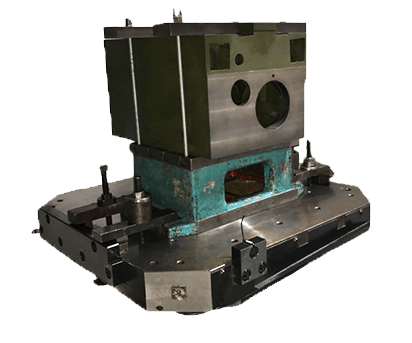

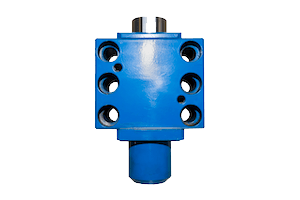

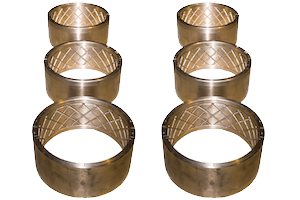

Everyone and all types of business benefit from having a 5S program. Manufacturing and industrial plants come to mind first, as those are the business that can realize the greatest benefits. However, any type of business, from a retail store to a power plant — from hospitals to television stations — all types of businesses, and all areas within a business, will realize benefits from implementing a 5S program.

What will 5S cost me?

The shipyard industry is spending nearly a million dollars to develop a Five S program the industry can use, and to implement that program at two shipyards. On the other hand you can implement a Five S program without adding an extra dollar to your budget.

Realistically you probably will need to spend some extra money to get your Five S program going. There will be training time; man-hours spent to get your facility cleaned up and organized; equipment purchases, such as buying a quality labeling system; and time spent on sustaining your Five S program once it is in place.

Your actual costs will depend on where you are now - for example what is the condition of your facility? The further you are from meeting the goals of a Five S program, the more it will cost to implement one and the greater the benefits you'll see as a result of your Five S program.

.png)

.png)

.png)

.png)

1png.png)