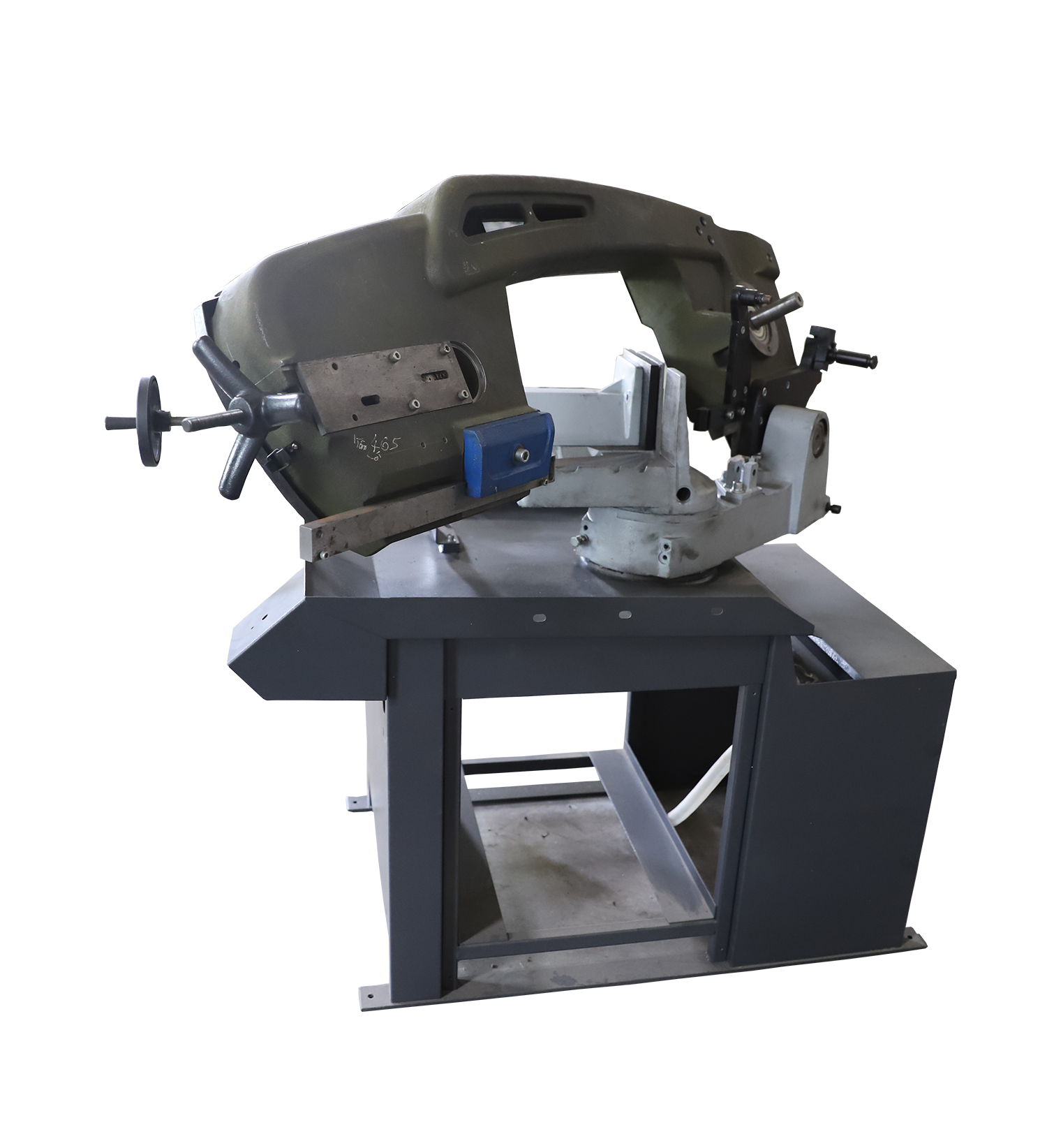

EXPLORE THE POWER OF THE HAMECO VERTICAL

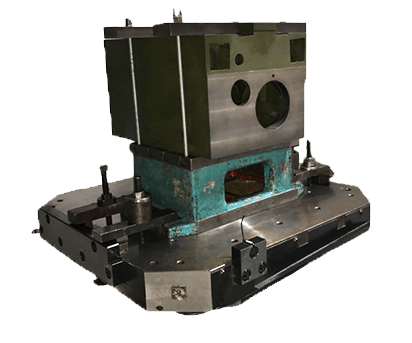

SHAFT IMPACT CRUSHER 2100

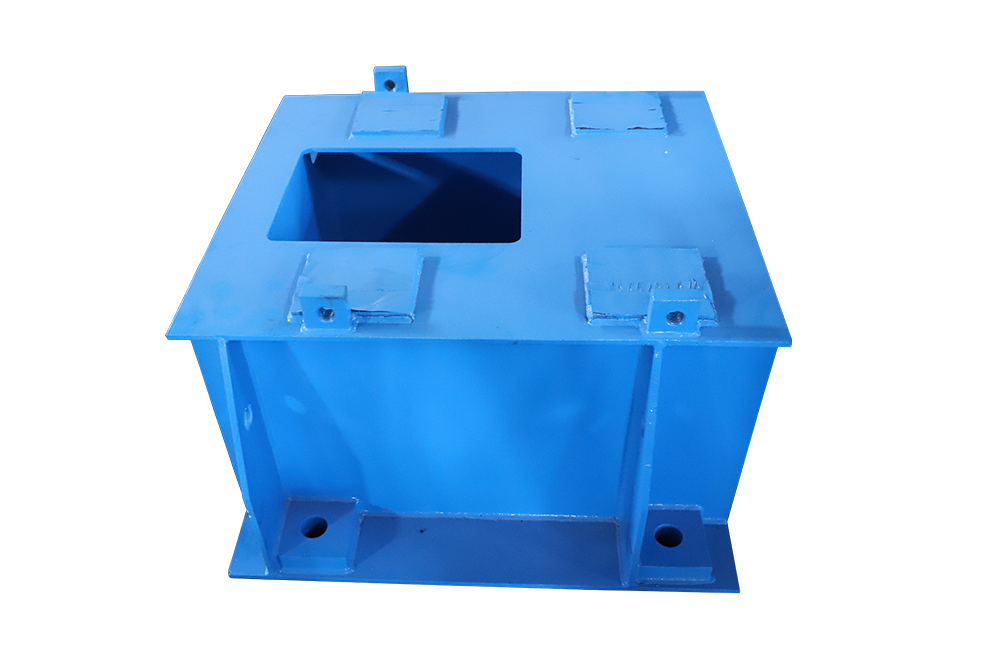

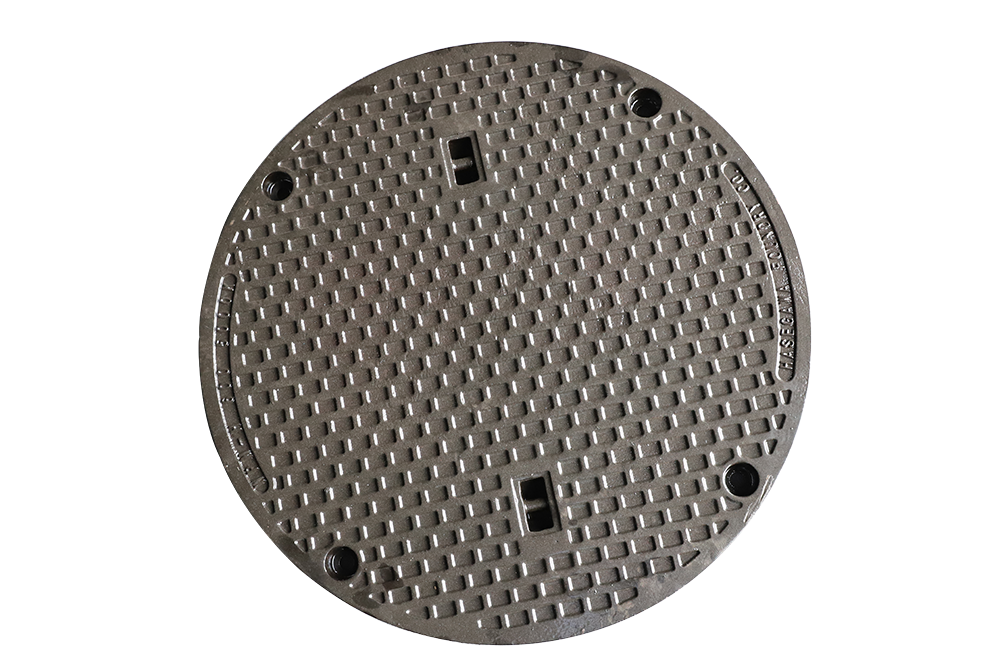

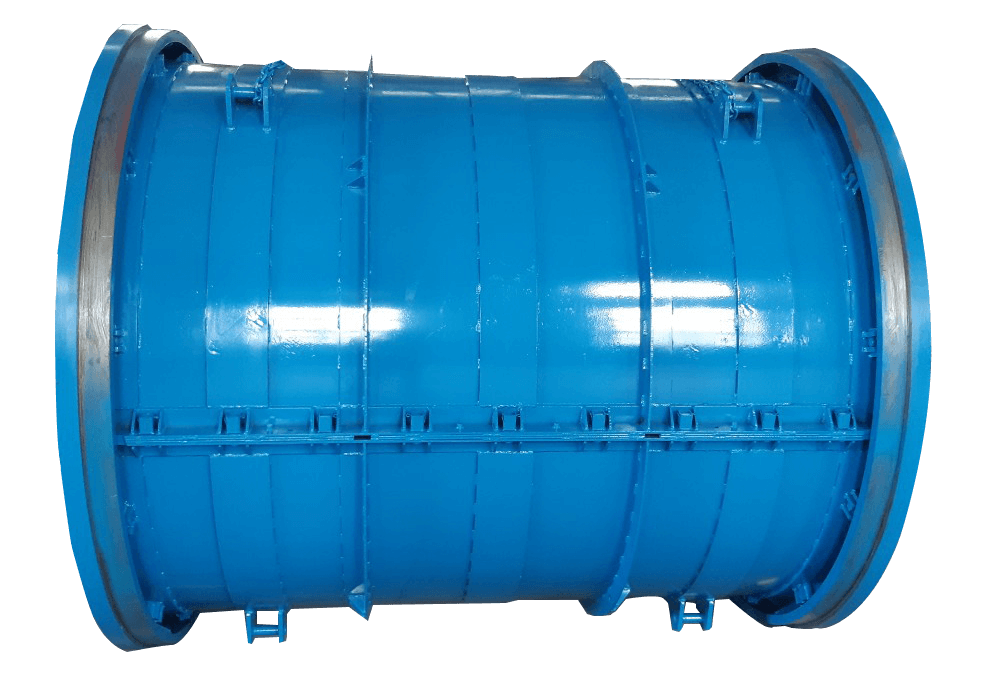

"Vertical shaft impact crusher" is an important equipment in the mineral

exploitation and processing industry. With an operating mechanism based on the

application of crushing force from a vertical shaft, this crusher is effective in

crushing stone and gravel into small particles suitable for use in construction,

industry, or other applications. Outstanding features of vertical shaft impact

crushers include high efficiency, energy saving, high durability and the ability to

flexibly adjust output product size. This is an indispensable tool in the modern

sand production and stone/gravel processing process.”

Are you looking for an effective and reliable solution for crushing stone and

gravel?

HAMECO vertical shaft impact crusher 2100 is your the ideal companion for all

mineral exploitation and processing jobs!

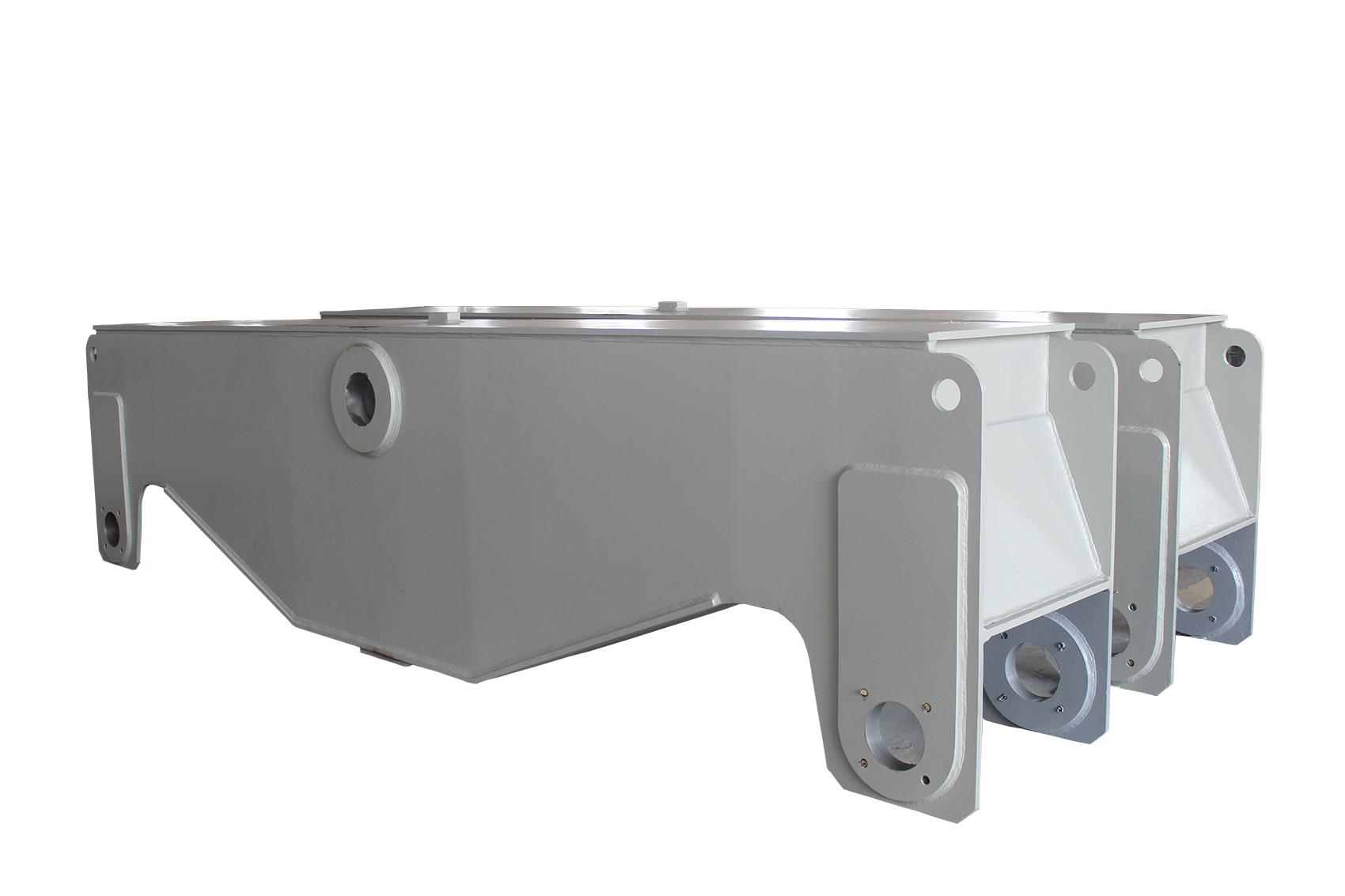

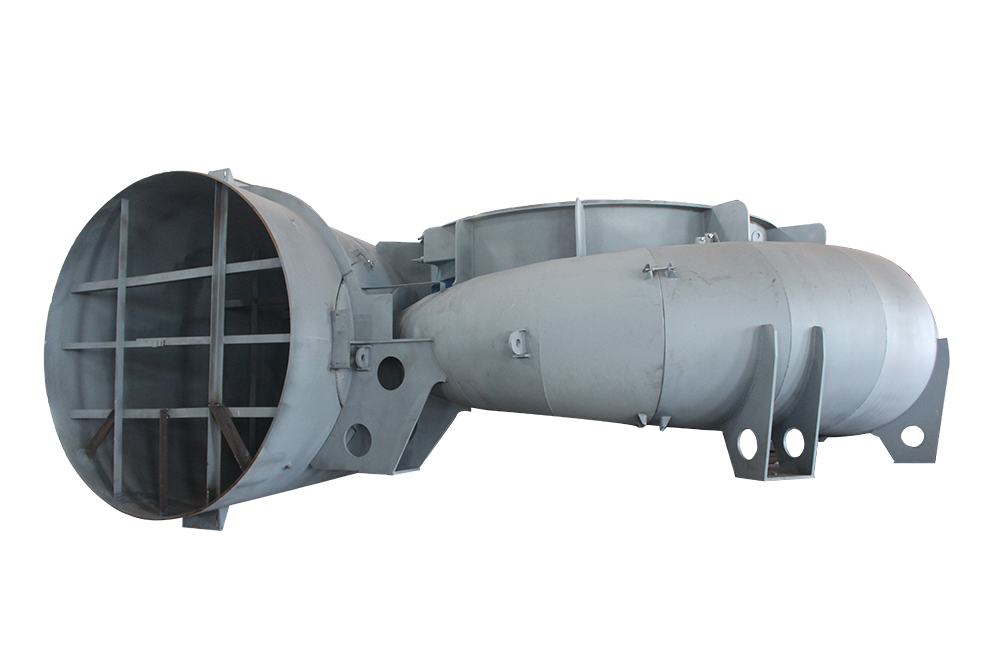

This is the result of the potential cooperation between Hameco and Sirocco

company - two leading names in the machinery and construction industry. We are

proud to introduce to you the Hameco vertical impact crusher 2100 - a perfect

combination of advanced technology and reliability.

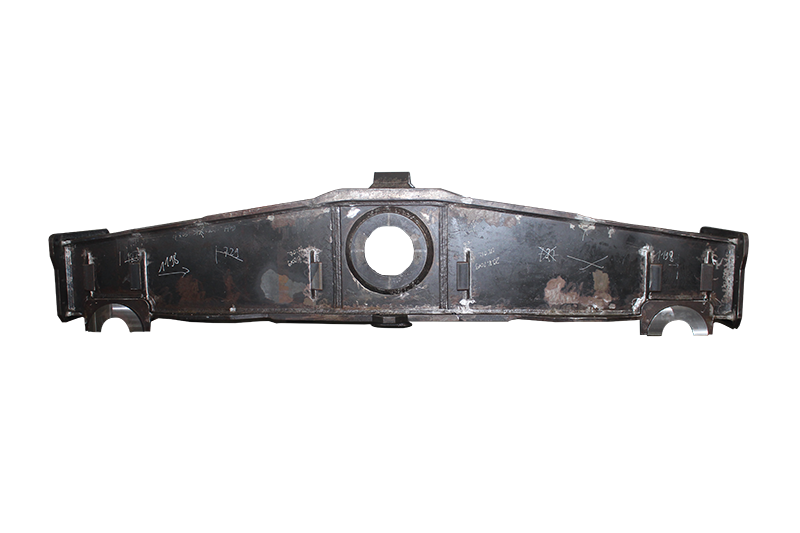

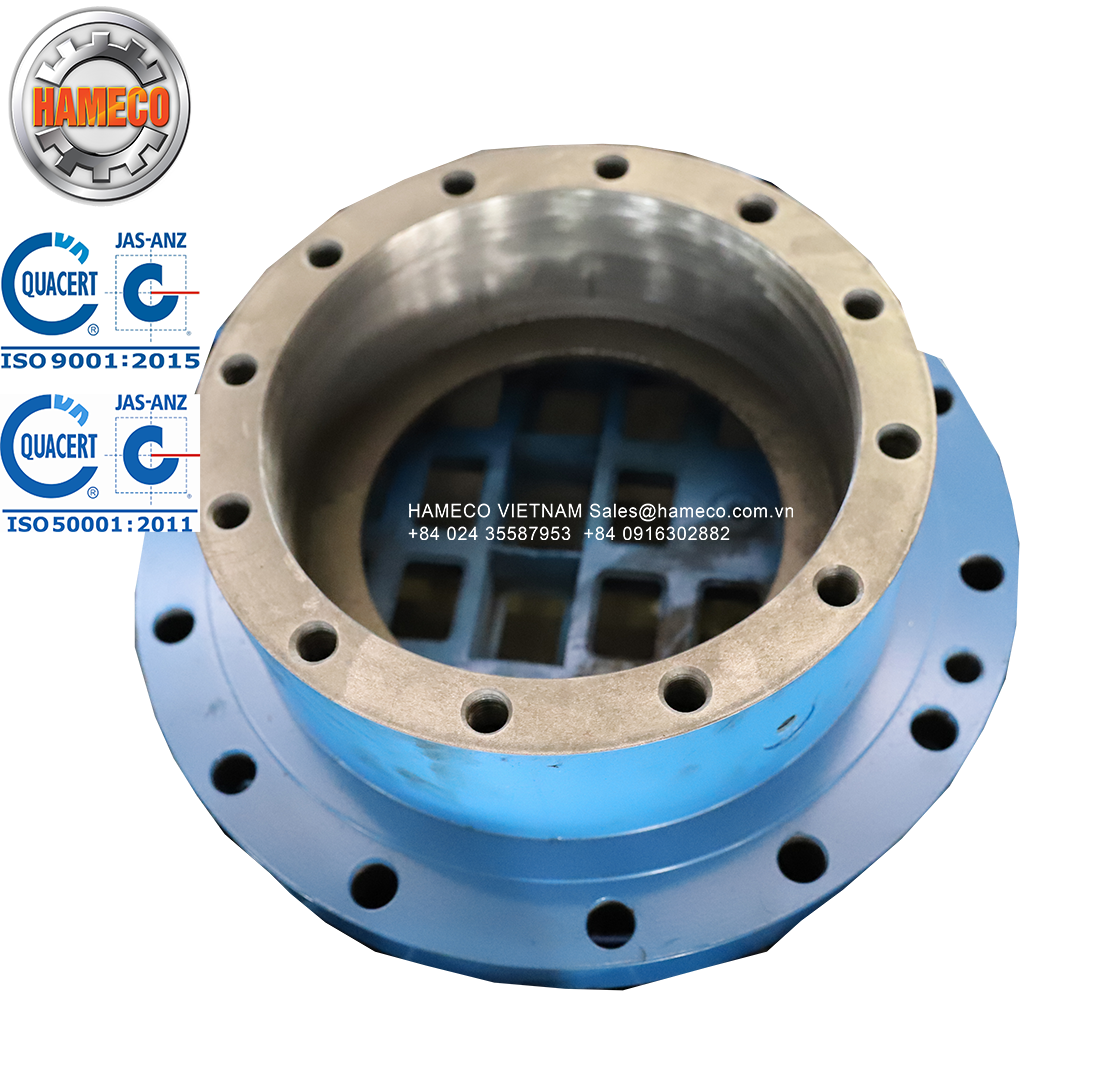

• With an intelligent operating mechanism, the vertical shaft impact crusher

not only crushes stone/gravel into small particles quickly and effectively

but also ensures the uniformity and quality of the final product.

• Not only crushing, vertical shaft impact crushers also have the ability to

adjust the output product size, thereby optimizing flexibility and meeting

all work requirements.

• With guaranteed performance, energy savings and outstanding durability,

vertical shaft impact crushers not only help increas

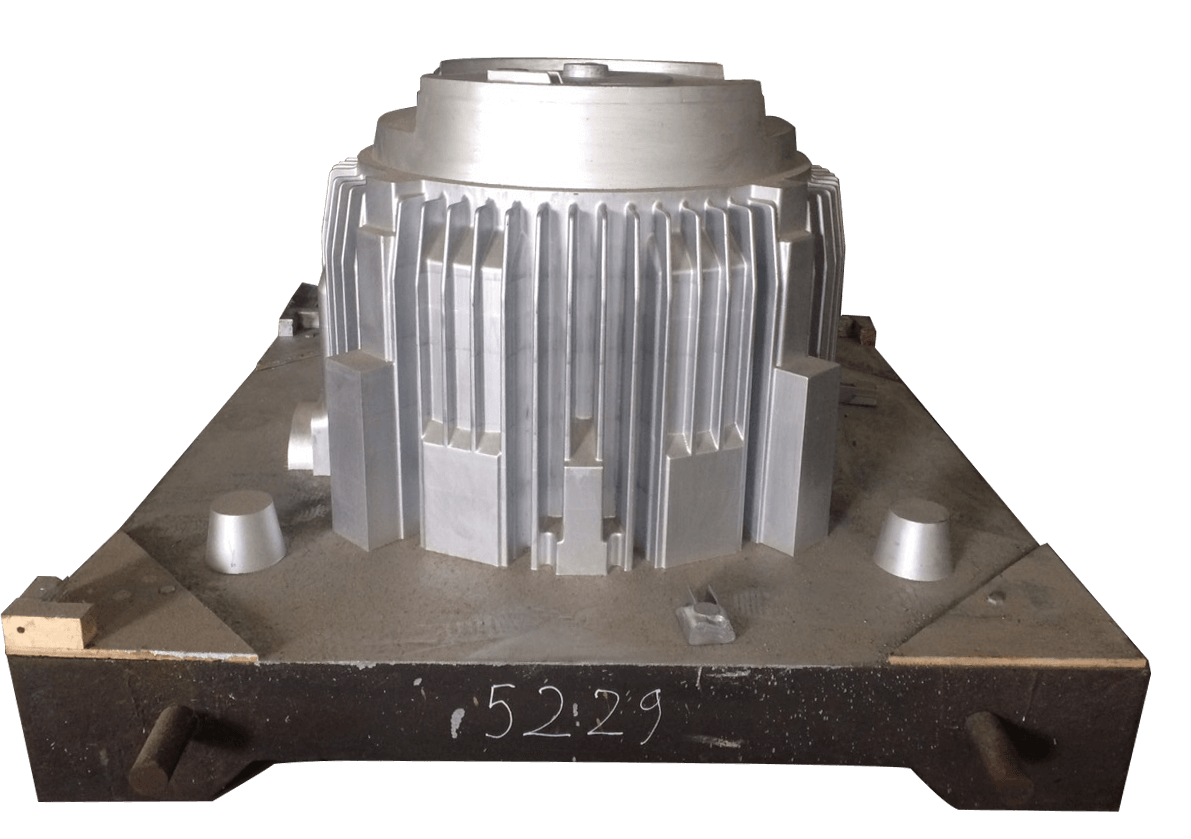

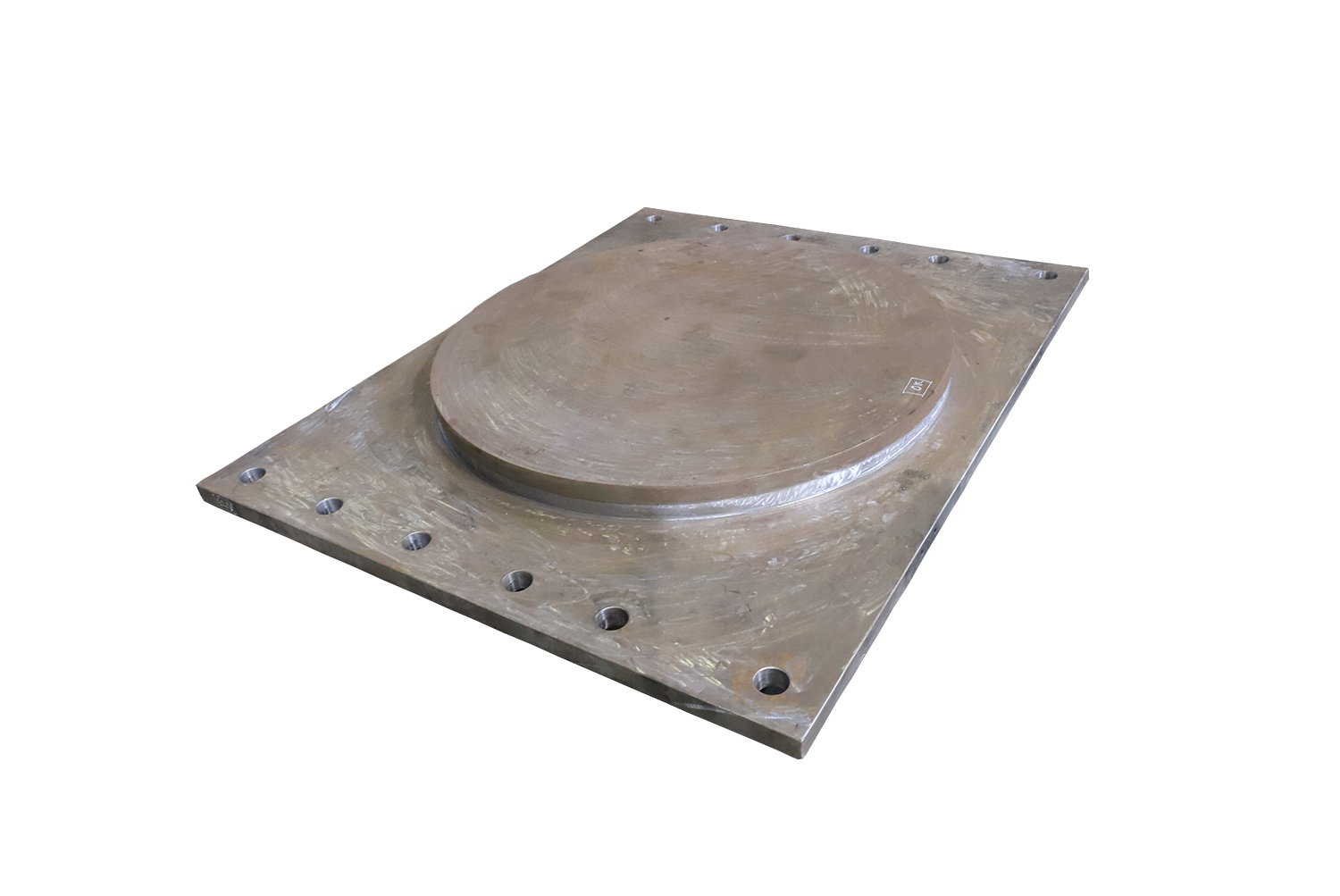

** Specifications of Hameco vertical shaft impact crusher2100 **

| Model | Hameco 2100 |

| Max. input size | 100 mm |

| Rotor speed | 800 – 2200 RPM |

| Drive motor | 90-220 Kw |

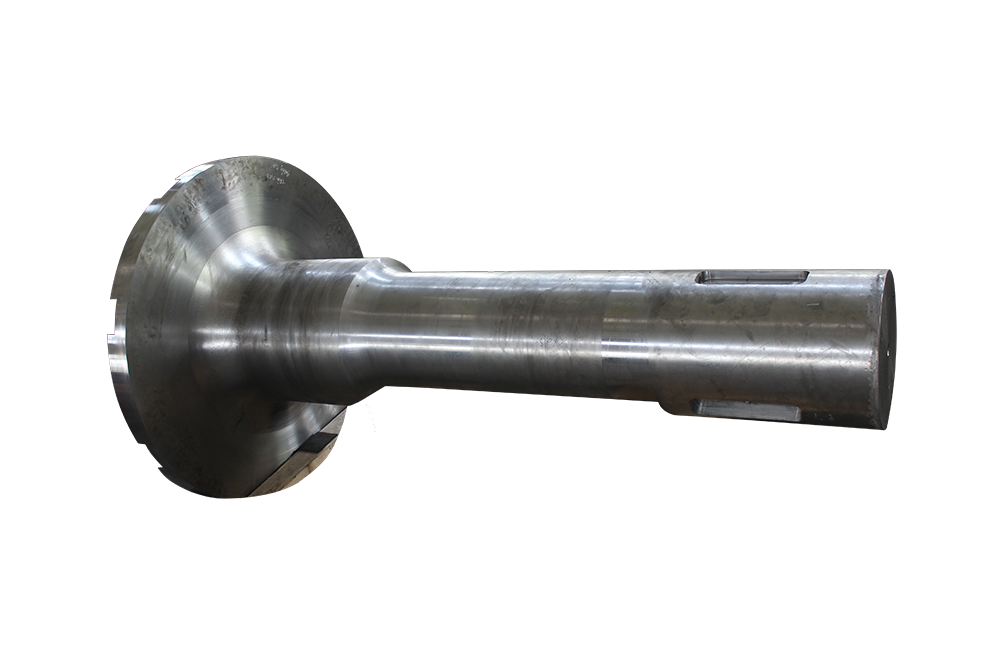

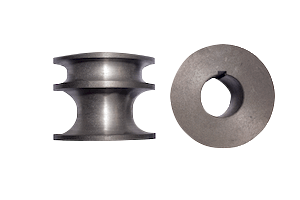

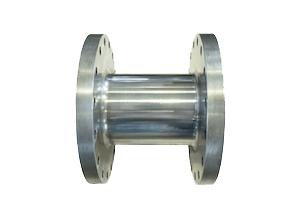

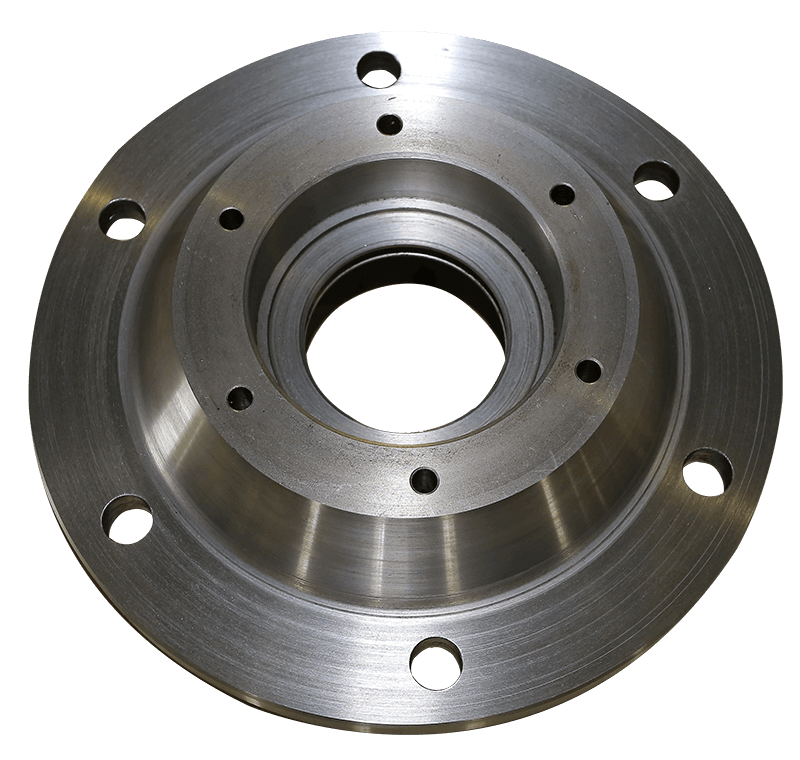

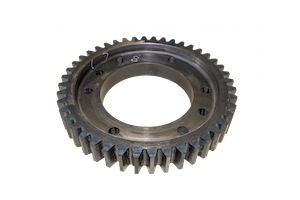

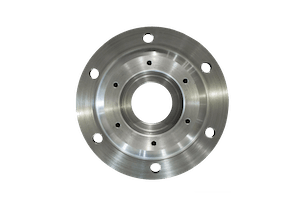

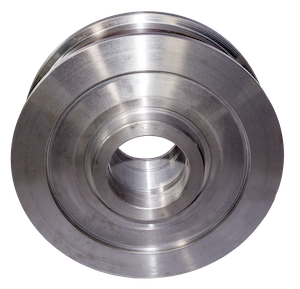

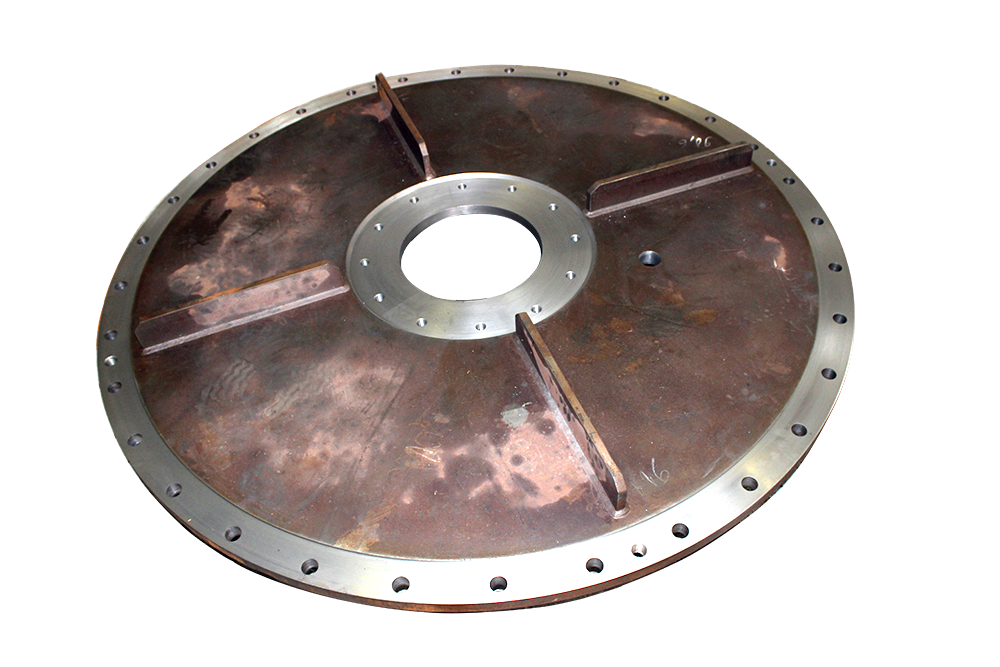

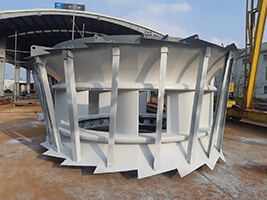

| Type of rotor | 3,4 or 5 port rotor-diam. from 600 to 1000mm |

| Crusher weight | 10,300 kg |

| Maximum capacity | 250t/h |

| Size of finished sand Grain | 0.25 mm-4 mm |

With the new HAMECO 2100 machine series, we are proud to have outstanding

advantages compared to other machine models on the market:

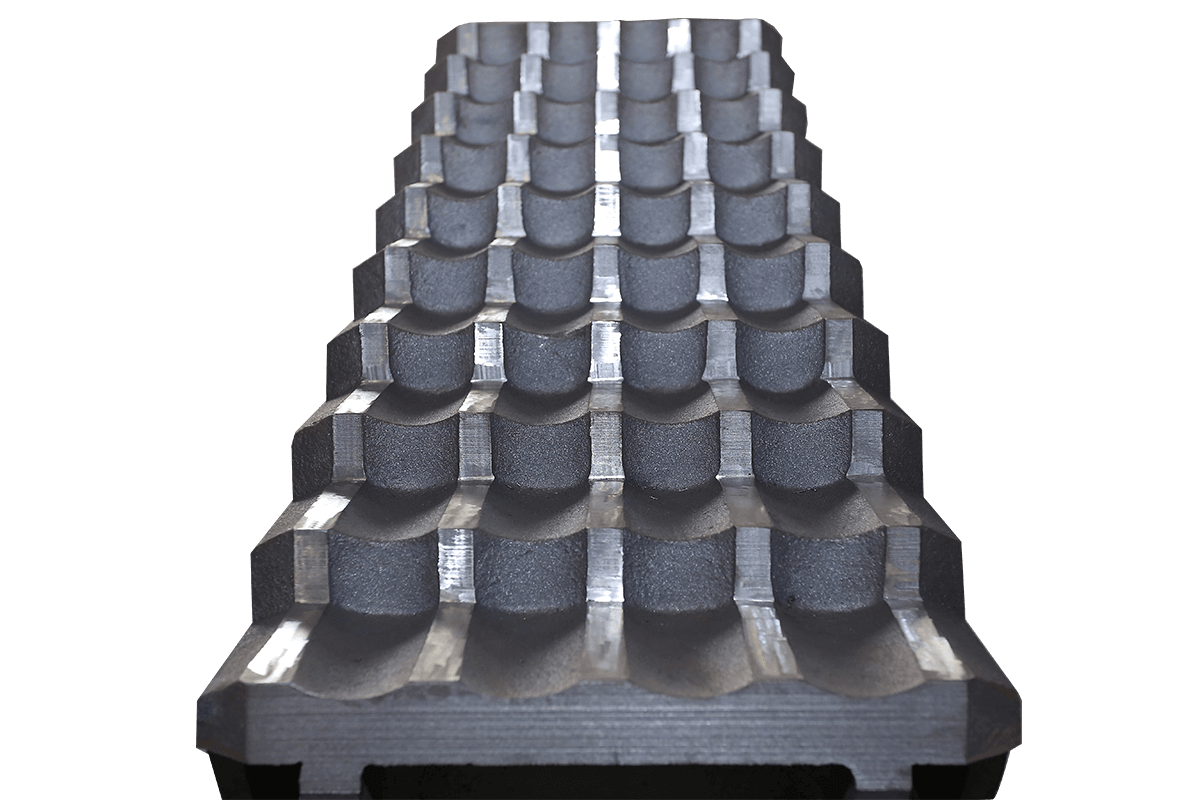

• Crush many types of input materials

• Soft stone elimination

• High capacity with large amount of output

• Low capital investment, low depreciation cost and quick capital recovery

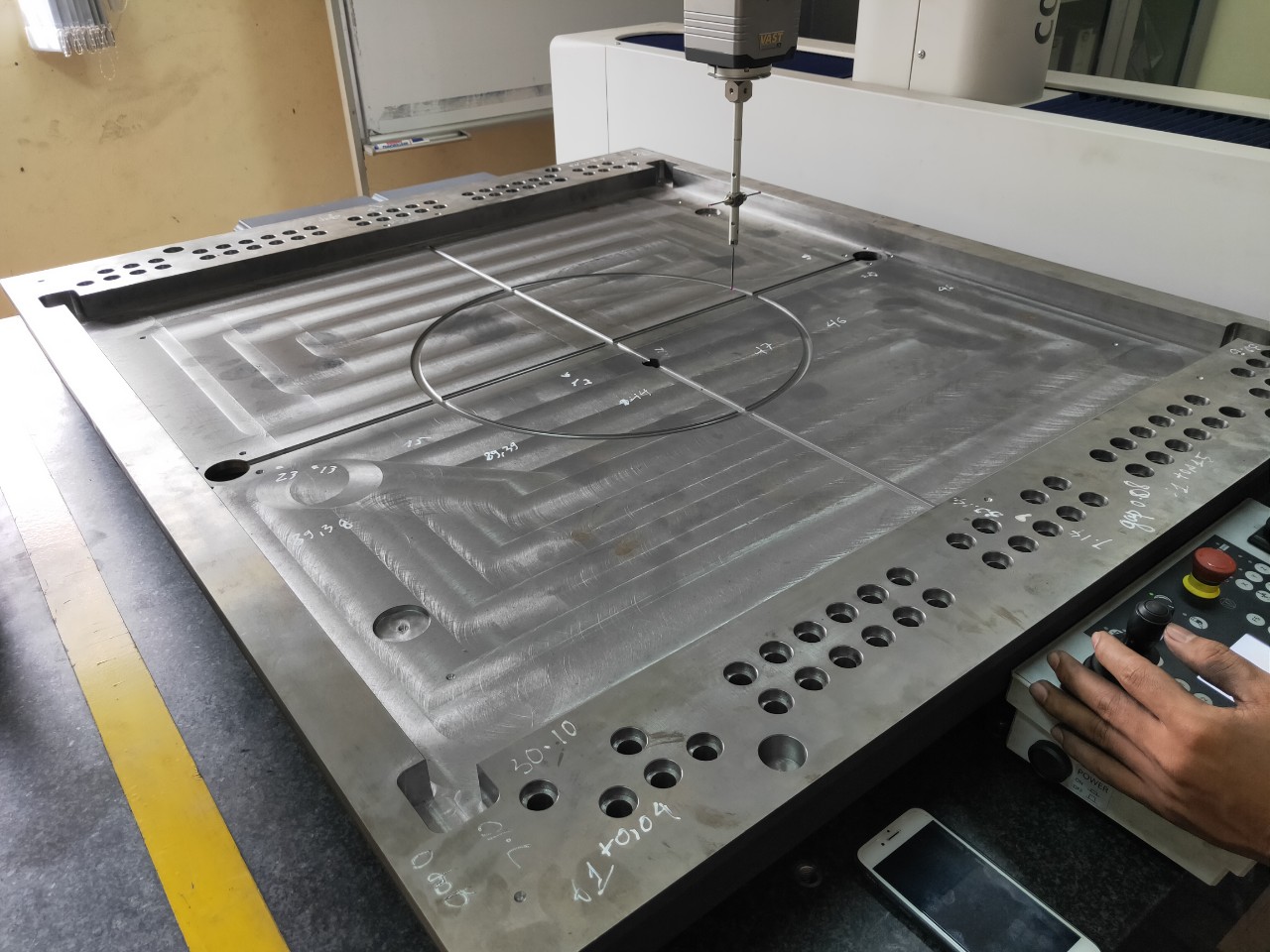

• Stable quality, high tonnage, round finished product shape, low flat particle

rate, easily installed and used, low wear costs.

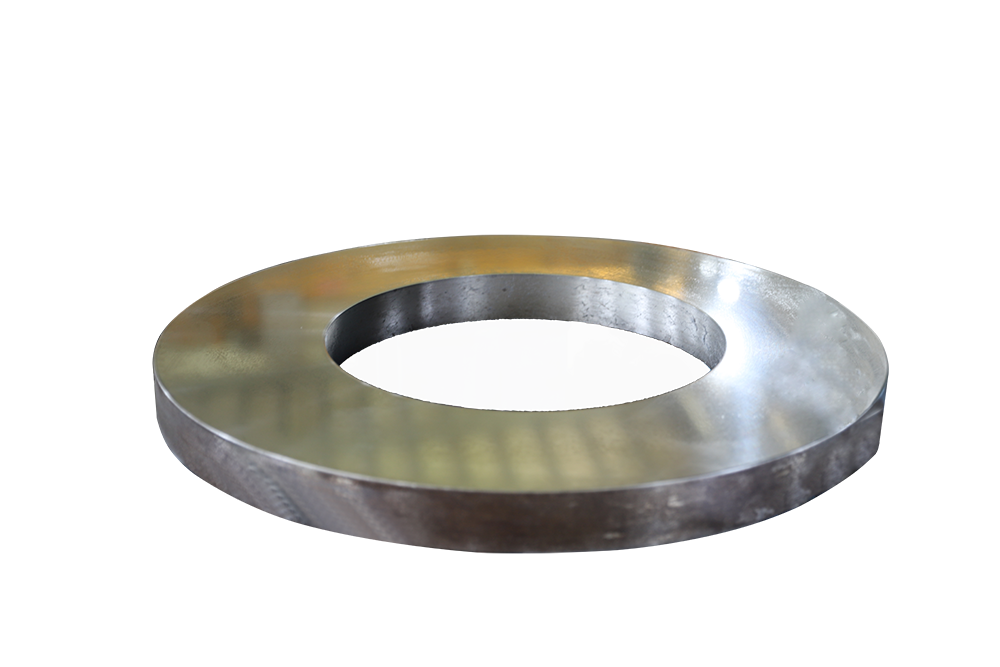

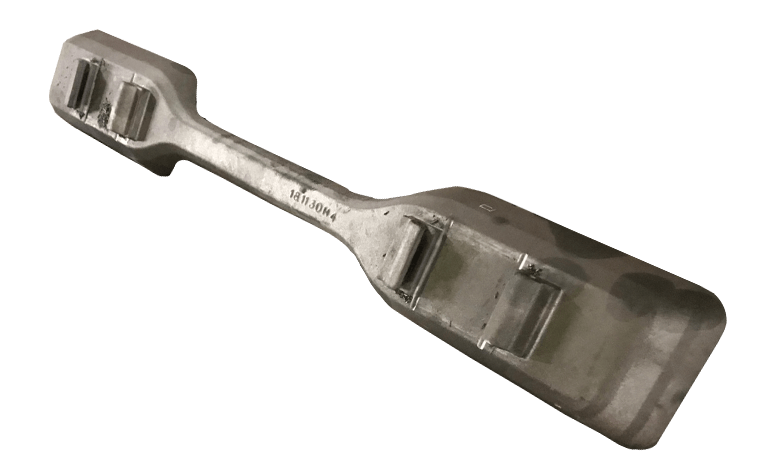

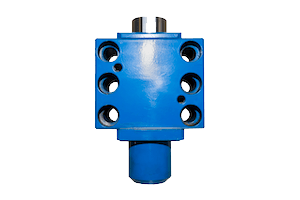

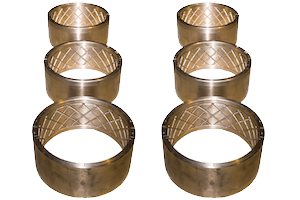

• Directly creates large energy to crush rocks into sand according to the

principle of Centrifugal Force, making the Rotor less worn, with low repair

and replacement costs.

• Fully automatic greasing system, ensuring continuous operation.

• Speed is controlled by inverter. If the machine is unstable, Vibration Sensor

will detect and stop the machine.

• Crushed sand products consists of both raw and soft sands.

** Come to see the Hameco Vertical Shaft Impact Crusher 2100 now at the Mining

& Construction Vietnam 2024 Exhibition! **

Don't miss the opportunity to explore the Hameco vertical shaft impact crusher

2100 at the Mining & Construction Vietnam 2024 Exhibition!

Come to our exhibition booth to receive professional advice and experience the

highest quality products.

• Time: from April 24 – 26, 2024

• Place: the National Exhibition Construction Center (NECC), No. 1 Do Duc

Duc - Me Tri - Nam Tu Niem - Hanoi - Vietnam

**Contact Hameco immediately for the earliest and most effective advice!**

“Let’s accompany HAMECO 2100 in the discovery of the power of vertical

shaft impact crushers - the perfect solution for all your work challenges!”

Purchase contact information:

Email : sales@hameco.com.vn / ktdt@hamecovietnam.vn/ kdtb@hamecovietnam.vn

Phone:+84 02435587953

Factory : Thuan Thanh 3 Industrial Zone ,Thanh Khuong, Thuan Thanh, Bac

Ninh, Viet Nam

Head office :76 Nguyen Trai ,Thanh Xuan, Hanoi, Vietnam

Website: hameco.com.vn

.png)

.png)

.png)

.png)

1png.png)